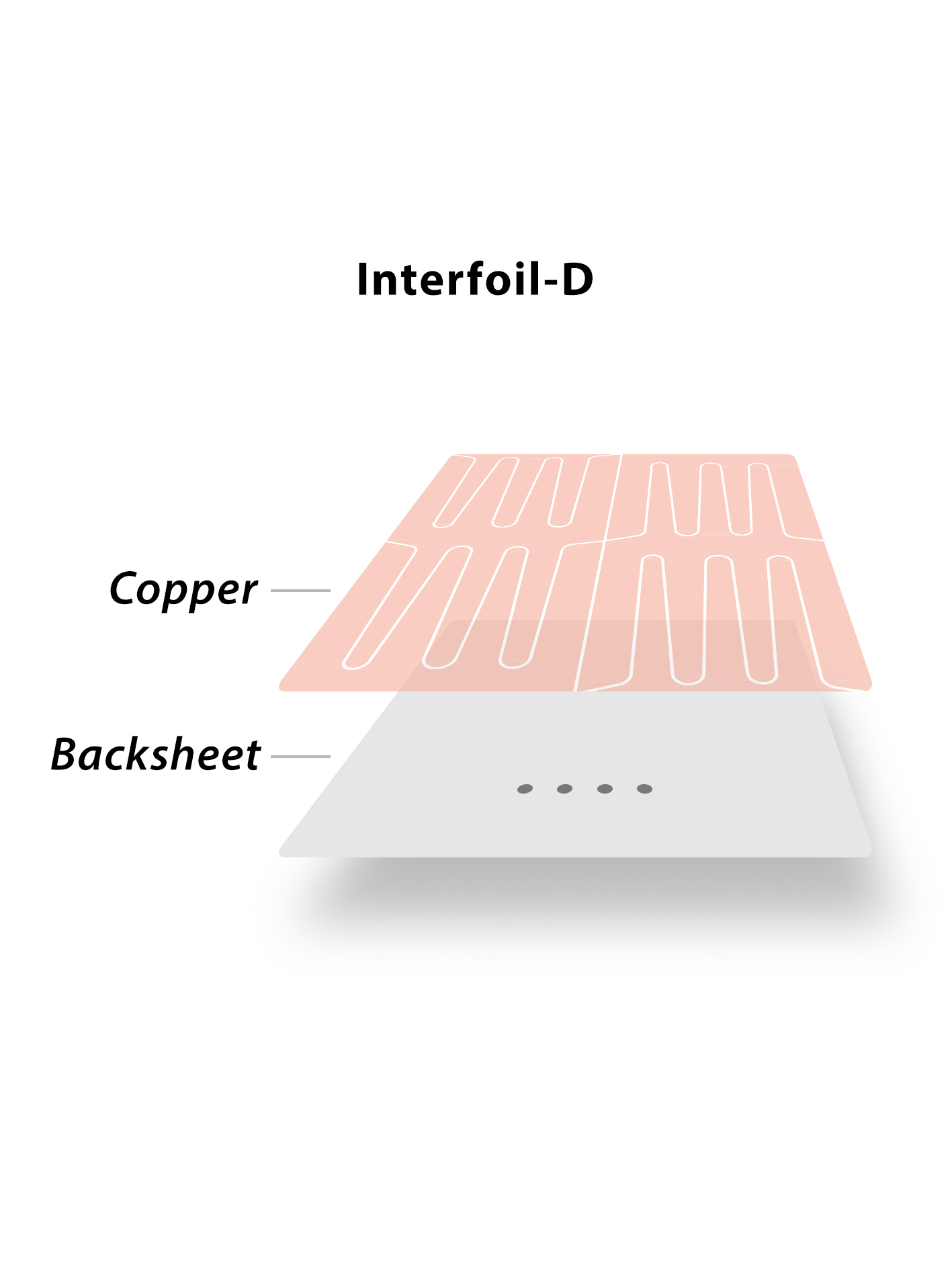

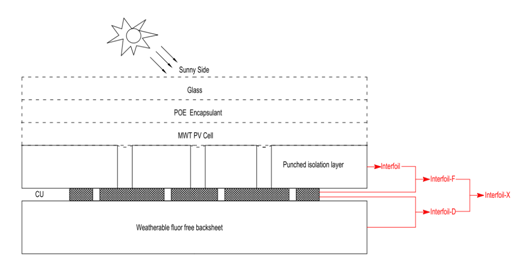

Interfoil-D

TYPE: Interfoil-D

|

No. |

Testing items |

Performance |

||||||

|

1 |

Total Thickness |

620 um |

||||||

|

2 |

structure |

Copper layer |

35 um |

|||||

|

EVA |

300 um |

|||||||

|

Backsheet |

FFC(EVA side) |

12 um |

||||||

|

PET |

285 um |

|||||||

|

FFC(Air side) |

13 um |

|||||||

|

3 |

Thickness deviation |

±5% |

||||||

|

4 |

Position accuracy of circuit diagram |

<±0.5 mm |

||||||

|

5 |

Position accuracy of holes |

<±0.5 mm |

||||||

|

6 |

Backsheet |

Tensile strength |

MD |

≥120N/mm2 GB/T13542.2-2009 |

||||

|

TD |

≥120N/mm2 GB/T13542.2-2009 |

|||||||

|

Elongation at break |

MD |

≥100% GB/T13542.2-2009 |

||||||

|

TD |

≥90% GB/T13542.2-2009 |

|||||||

|

Heat shrinkage@150℃ 30min |

MD |

≤1 % GB/T13542.2-2009 |

||||||

|

TD |

≤1 % GB/T13542.2-2009 |

|||||||

|

Coating adhesion |

0 grade GB/T9286-1998 |

|||||||

|

Peeling strength with EVA (Initial) |

≥45 N/cm GB/T2790-1995 |

|||||||

|

Peeling strength with EVA (85℃*85%RH,1000h) |

≥40 N/cm GB/T2790-1995 |

|||||||

|

Partial discharge |

≥1500 v IEC60664-1-2007 |

|||||||

|

Breakdown voltage |

≥18 Kv GB/T13542.2-2009 |

|||||||

|

Moisture vapor transmission rate |

≤2.5 g/m2﹒d GB/T26253-2010 |

|||||||

|

Damp-heat Testing(85℃*85%RH,2000h) |

No delamination , no bubble,Δb≤2 IEC61215-2005 |

|||||||

|

UV pretreatment(60kWh/m2) |

No delamination , no bubble or fold,Δb≤2 IEC61215-2005 |

|||||||

|

Boiling water treatment(boil for 24h) |

Visually inspect |

No delamination , no bubble or fold, no peeling or powdering GB/T17748-2008 |

||||||

|

Coating adhesion |

0 grade GB/T9286-1998 |

|||||||

|

Fluor content |

fluor free |

|||||||

|

Note: The backsheet is customized, and the above data is for reference only. |

||||||||